Exploring the Benefits of Durable Polycarbonate Vacuum Forming Machines

2025-10-25

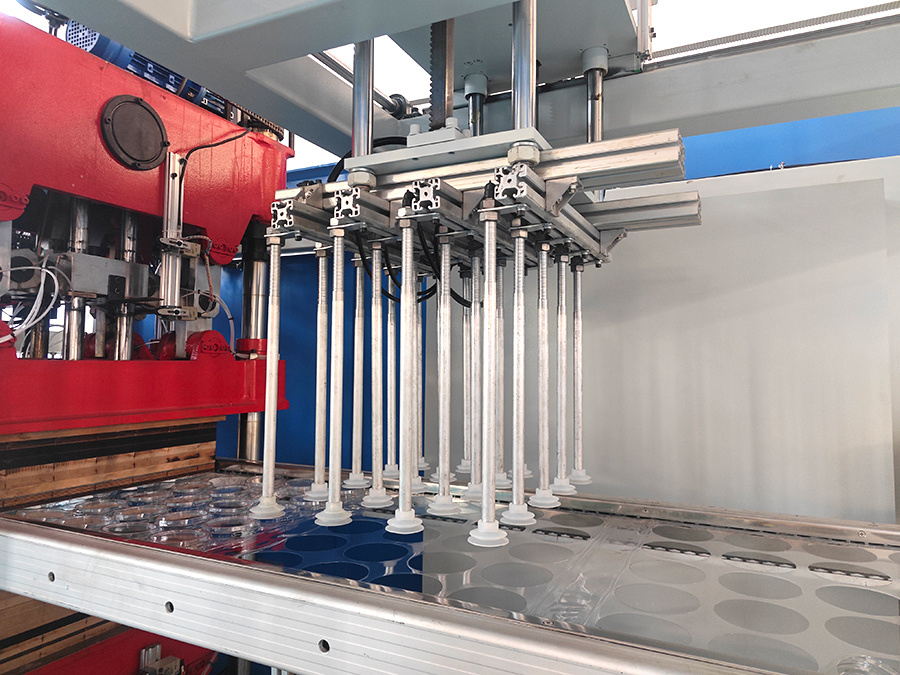

In the realm of manufacturing and processing machinery, durable polycarbonate vacuum forming machines play a crucial role, particularly in the packaging industry. These machines utilize a process that involves heating a sheet of polycarbonate plastic until it becomes pliable, then forming it over a mold using vacuum pressure. This method is not only efficient but also provides a range of benefits that make it ideal for various applications.

One of the key advantages of using polycarbonate in vacuum forming is its inherent durability. Polycarbonate is a strong thermoplastic that can withstand significant impacts and is resistant to UV radiation, making it an excellent choice for products that require longevity and stability. This durability ensures that items created through this process maintain their integrity over time, which is especially important for packaging that must protect its contents.

Moreover, vacuum forming machines designed for polycarbonate can produce complex shapes with precision. The ability to create detailed and intricate designs means that manufacturers can develop customized packaging solutions tailored to specific product requirements. Whether it's for electronics, food containers, or medical supplies, the versatility of durable polycarbonate vacuum forming machines allows for innovative packaging designs that enhance product visibility and consumer appeal.

Efficiency is another significant benefit of using these machines. The vacuum forming process is generally faster than other forming methods, such as injection molding, particularly for low to medium production runs. This speed translates to reduced production times, which can be crucial for businesses looking to meet market demands swiftly. Additionally, the energy consumption in the vacuum forming process can be lower compared to other methods, contributing to more sustainable manufacturing practices.

Furthermore, the ease of maintenance and operation of durable polycarbonate vacuum forming machines makes them a favorable choice for manufacturers. Many modern machines come equipped with user-friendly interfaces and require minimal training for operators. This accessibility leads to reduced downtime and higher productivity rates, ensuring that businesses can maintain a competitive edge in the market.

Durable polycarbonate vacuum forming machines represent a valuable investment for manufacturers in the packaging industry. Their strength, versatility, efficiency, and ease of use make them an ideal choice for creating high-quality packaging solutions. As businesses continue to seek ways to optimize their production processes and meet consumer needs, the adoption of these machines will likely become increasingly prevalent, paving the way for innovation and improved product offerings.

Keywords:

Polycarbonate vacuum forming machine

Related information

Discover the Transformative Benefits of a New Industrial Vacuum Former for Your Business

2025-11-03

Exploring the Key Features of Renowned Thermoforming Press Machines

2025-10-31

Unlocking Efficiency: The Role of Classy ABS Vacuum Forming Machines in Modern Manufacturing

2025-10-28