Understanding Durable Vacuum Forming Equipment: Key Insights for Efficient Plastic Processing

2025-07-14

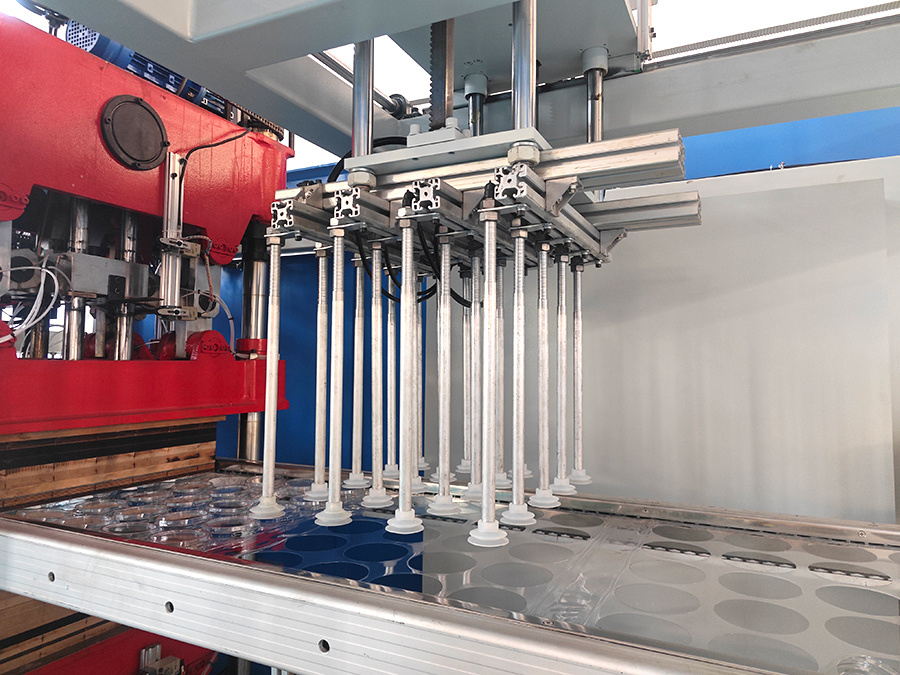

Vacuum forming is a popular plastic processing method used to create various products by heating plastic sheets and forming them over a mold using vacuum pressure. Durable vacuum forming equipment is crucial for manufacturers looking to optimize their production lines and achieve high-quality results.

One of the primary benefits of investing in durable vacuum forming equipment is its ability to wi

Vacuum forming is a popular plastic processing method used to create various products by heating plastic sheets and forming them over a mold using vacuum pressure. Durable vacuum forming equipment is crucial for manufacturers looking to optimize their production lines and achieve high-quality results.

One of the primary benefits of investing in durable vacuum forming equipment is its ability to withstand the rigors of continuous use. High-quality machines are designed with robust materials and advanced engineering techniques that ensure longevity and reliability. This durability minimizes downtime, which is essential for maintaining productivity in a manufacturing environment. When equipment frequently breaks down or requires maintenance, it can lead to significant financial losses and delays in production schedules.

Furthermore, durable vacuum forming equipment often comes equipped with advanced features that enhance operational efficiency. Modern machines may include programmable controls, which allow for precise adjustments to temperature and pressure settings. This level of control is vital for achieving consistent product quality, as variations in these parameters can lead to defects or subpar results. By using equipment with such capabilities, manufacturers can ensure that their products meet stringent quality standards, ultimately leading to higher customer satisfaction.

In addition to efficiency and reliability, durable vacuum forming equipment can also contribute to sustainability efforts in plastic processing. Many modern machines are designed to reduce material waste through better mold design and precise heating methods. This not only minimizes the environmental impact of manufacturing processes but also lowers material costs, making operations more economically viable.

Additionally, the versatility of vacuum forming equipment allows manufacturers to create a wide range of products, from packaging to automotive components. The ability to produce custom shapes and sizes enables businesses to cater to diverse market demands. Investing in durable equipment ensures that manufacturers can adapt to changing market needs without compromising on quality or efficiency.

When selecting vacuum forming equipment, it is essential to consider not only the initial cost but also the long-term benefits of durability and performance. Understanding the specific requirements of your production processes and seeking out machines that align with these needs will ultimately lead to more successful manufacturing operations.

In conclusion, durable vacuum forming equipment plays a vital role in the efficiency and effectiveness of plastic processing in the manufacturing sector. By investing in high-quality machinery, businesses can enhance their production capabilities, reduce waste, and improve product quality, which are all essential components for staying competitive in today’s market.

One of the primary benefits of investing in durable vacuum forming equipment is its ability to withstand the rigors of continuous use. High-quality machines are designed with robust materials and advanced engineering techniques that ensure longevity and reliability. This durability minimizes downtime, which is essential for maintaining productivity in a manufacturing environment. When equipment frequently breaks down or requires maintenance, it can lead to significant financial losses and delays in production schedules.

Furthermore, durable vacuum forming equipment often comes equipped with advanced features that enhance operational efficiency. Modern machines may include programmable controls, which allow for precise adjustments to temperature and pressure settings. This level of control is vital for achieving consistent product quality, as variations in these parameters can lead to defects or subpar results. By using equipment with such capabilities, manufacturers can ensure that their products meet stringent quality standards, ultimately leading to higher customer satisfaction.

In addition to efficiency and reliability, durable vacuum forming equipment can also contribute to sustainability efforts in plastic processing. Many modern machines are designed to reduce material waste through better mold design and precise heating methods. This not only minimizes the environmental impact of manufacturing processes but also lowers material costs, making operations more economically viable.

Additionally, the versatility of vacuum forming equipment allows manufacturers to create a wide range of products, from packaging to automotive components. The ability to produce custom shapes and sizes enables businesses to cater to diverse market demands. Investing in durable equipment ensures that manufacturers can adapt to changing market needs without compromising on quality or efficiency.

When selecting vacuum forming equipment, it is essential to consider not only the initial cost but also the long-term benefits of durability and performance. Understanding the specific requirements of your production processes and seeking out machines that align with these needs will ultimately lead to more successful manufacturing operations.

In conclusion, durable vacuum forming equipment plays a vital role in the efficiency and effectiveness of plastic processing in the manufacturing sector. By investing in high-quality machinery, businesses can enhance their production capabilities, reduce waste, and improve product quality, which are all essential components for staying competitive in today’s market.

Keywords:

Related information

Understanding Durable Vacuum Forming Equipment: Key Insights for Efficient Plastic Processing

Vacuum forming is a popular plastic processing method used to create various products by heating plastic sheets and forming them over a mold using vacuum pressure. Durable vacuum forming equipment is crucial for manufacturers looking to optimize their production lines and achieve high-quality results.

One of the primary benefits of investing in durable vacuum forming equipment is its ability to wi

2025-07-14

Unlocking Efficiency: The Role of Advanced Pressure Forming Machines in Modern Manufacturing

Unlocking Efficiency: The Role of Advanced Pressure Forming Machines in Modern Manufacturing

Table of Contents

Introduction to Advanced Pressure Forming Machines

What is Pressure Forming in Plastic Manufacturing?

Benefits of Advanced Pressure Forming Machines

How Pressure Forming Works: A Step-by-Step Guide

Materials Used in Pressure Forming Processes

Applications of Pressure Forming

2025-07-13

The Innovative World of Discount Sheet Forming Machines: Transforming Manufacturing Processes

In the ever-evolving landscape of manufacturing and packaging machinery, the discount sheet forming machine stands out as a remarkable innovation. This machine is specifically designed to create various sheet forms, making it essential for companies looking to optimize their manufacturing processes. Understanding how these machines work and their benefits can be invaluable for businesses aiming to

2025-07-12