Exploring the Advantages of Classy Automatic Thermoforming Machines

2025-07-16

In the realm of packaging machinery, the classy automatic thermoforming machine stands out as a sophisticated and efficient solution for producing a wide variety of plastic products. These machines are designed to create packaging by heating plastic sheets until they become pliable and then forming them into specific shapes using molds. This process not only enhances the aesthetic appeal of the pa

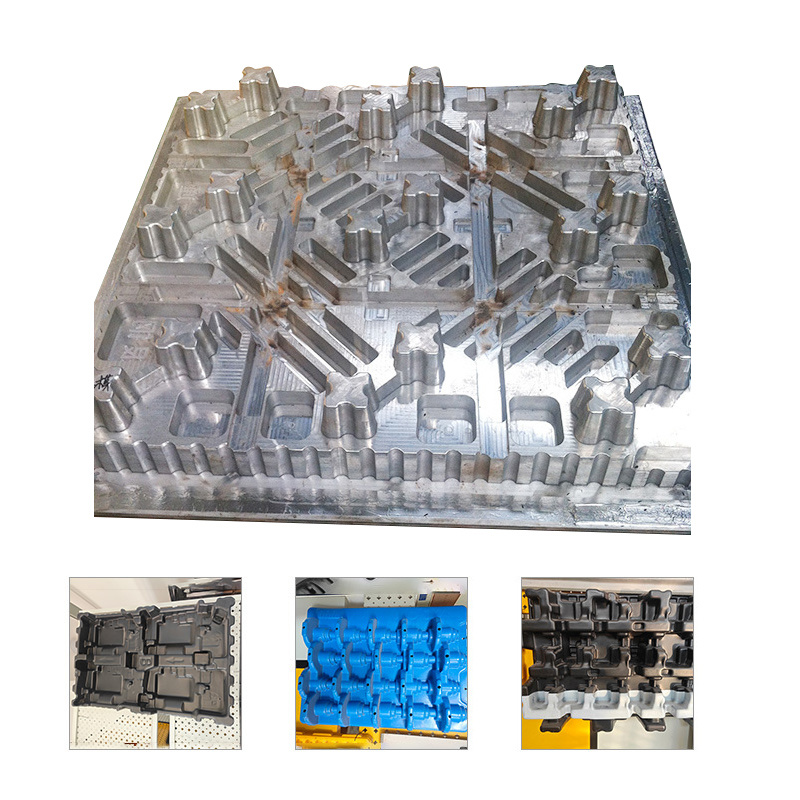

In the realm of packaging machinery, the classy automatic thermoforming machine stands out as a sophisticated and efficient solution for producing a wide variety of plastic products. These machines are designed to create packaging by heating plastic sheets until they become pliable and then forming them into specific shapes using molds. This process not only enhances the aesthetic appeal of the packaging but also improves functionality, making it a preferred choice among manufacturers.

One of the primary advantages of a classy automatic thermoforming machine is its efficiency. These machines are equipped with advanced automation features that streamline the manufacturing process. This means that manufacturers can achieve higher output rates while maintaining consistent quality in their products. In today's fast-paced market, the ability to produce large quantities of packaging swiftly can provide a significant competitive edge.

Moreover, classy automatic thermoforming machines offer versatility in terms of design and material compatibility. Manufacturers can easily adapt these machines to work with various types of plastics, allowing for experimentation with different designs and features. This flexibility is crucial for businesses looking to cater to diverse customer needs and market trends. Whether it’s creating clamshell packaging, blisters, or complex shapes, these machines can efficiently meet the demands of various industries such as food and beverage, electronics, and consumer goods.

Additionally, energy efficiency is a key consideration in modern manufacturing, and classy automatic thermoforming machines are designed with this in mind. By optimizing energy consumption during the heating and forming processes, these machines not only reduce operational costs but also minimize the environmental impact associated with packaging production. This aligns with the growing trend towards sustainability in manufacturing, making these machines an attractive option for eco-conscious businesses.

The ease of operation and maintenance of classy automatic thermoforming machines also contributes to their appeal. With user-friendly interfaces and automated settings, operators can quickly learn how to use these machines effectively, reducing training time and labor costs. Furthermore, the design of these machines often includes features that simplify maintenance tasks, ensuring they remain in optimal working condition with minimal downtime.

In conclusion, classy automatic thermoforming machines are a vital component in the packaging machinery sector, offering a blend of efficiency, versatility, and sustainability. Their ability to produce high-quality packaging solutions quickly and cost-effectively makes them an essential tool for manufacturers looking to enhance their product offerings and stay ahead in a competitive market. As industries continue to evolve, the role of these machines will undoubtedly expand, paving the way for innovative packaging solutions that meet the needs of both manufacturers and consumers alike.

One of the primary advantages of a classy automatic thermoforming machine is its efficiency. These machines are equipped with advanced automation features that streamline the manufacturing process. This means that manufacturers can achieve higher output rates while maintaining consistent quality in their products. In today's fast-paced market, the ability to produce large quantities of packaging swiftly can provide a significant competitive edge.

Moreover, classy automatic thermoforming machines offer versatility in terms of design and material compatibility. Manufacturers can easily adapt these machines to work with various types of plastics, allowing for experimentation with different designs and features. This flexibility is crucial for businesses looking to cater to diverse customer needs and market trends. Whether it’s creating clamshell packaging, blisters, or complex shapes, these machines can efficiently meet the demands of various industries such as food and beverage, electronics, and consumer goods.

Additionally, energy efficiency is a key consideration in modern manufacturing, and classy automatic thermoforming machines are designed with this in mind. By optimizing energy consumption during the heating and forming processes, these machines not only reduce operational costs but also minimize the environmental impact associated with packaging production. This aligns with the growing trend towards sustainability in manufacturing, making these machines an attractive option for eco-conscious businesses.

The ease of operation and maintenance of classy automatic thermoforming machines also contributes to their appeal. With user-friendly interfaces and automated settings, operators can quickly learn how to use these machines effectively, reducing training time and labor costs. Furthermore, the design of these machines often includes features that simplify maintenance tasks, ensuring they remain in optimal working condition with minimal downtime.

In conclusion, classy automatic thermoforming machines are a vital component in the packaging machinery sector, offering a blend of efficiency, versatility, and sustainability. Their ability to produce high-quality packaging solutions quickly and cost-effectively makes them an essential tool for manufacturers looking to enhance their product offerings and stay ahead in a competitive market. As industries continue to evolve, the role of these machines will undoubtedly expand, paving the way for innovative packaging solutions that meet the needs of both manufacturers and consumers alike.

Keywords:

Related information

Harnessing Data Analytics to Enhance Performance in Renowned Forming Equipment

Harnessing Data Analytics to Enhance Performance in Renowned Forming Equipment

Table of Contents

Introduction to Data Analytics in Forming Equipment

The Importance of Data Analytics in Manufacturing

Key Data Analytics Techniques for Forming Equipment

Real-World Case Studies of Data Analytics in Action

Challenges in Harnessing Data Analytics

Future Trends in Data Analytics

2025-07-17

Exploring the Advantages of Classy Automatic Thermoforming Machines

In the realm of packaging machinery, the classy automatic thermoforming machine stands out as a sophisticated and efficient solution for producing a wide variety of plastic products. These machines are designed to create packaging by heating plastic sheets until they become pliable and then forming them into specific shapes using molds. This process not only enhances the aesthetic appeal of the pa

2025-07-16

Unlocking the Potential: Why a Fancy Blister Thermoforming Machine is Essential for Your Production Line

Table of Contents

Introduction to Blister Thermoforming Machines

What is Thermoforming?

Benefits of Fancy Blister Thermoforming Machines

Enhanced Efficiency in Production

Cost Reduction and Resource Optimization

Improved Product Quality

2025-07-15