The Future of Manufacturing: Investing in a New Home Vacuum Forming Machine

2025-07-18

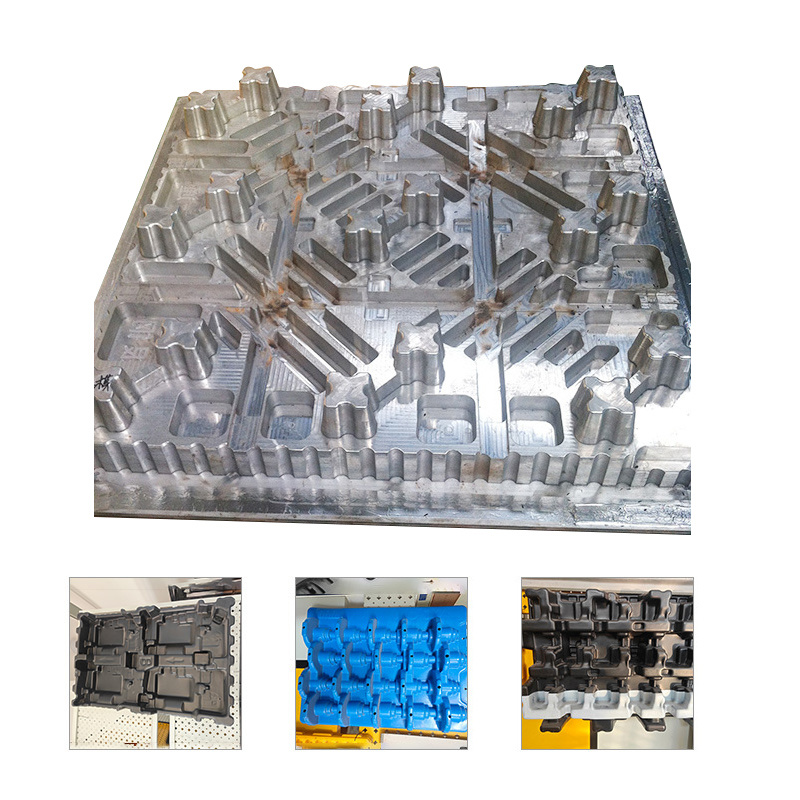

In the landscape of manufacturing and packaging machinery, the introduction of a new home vacuum forming machine can significantly transform production capabilities. Vacuum forming is a widely used method for creating plastic parts and packaging, which involves heating a thermoplastic sheet until it is pliable, then forming it over a mold using vacuum pressure. This technology is not only versatil

In the landscape of manufacturing and packaging machinery, the introduction of a new home vacuum forming machine can significantly transform production capabilities. Vacuum forming is a widely used method for creating plastic parts and packaging, which involves heating a thermoplastic sheet until it is pliable, then forming it over a mold using vacuum pressure. This technology is not only versatile but also cost-effective, making it an attractive option for manufacturers looking to innovate and streamline their operations.

One of the primary benefits of a new home vacuum forming machine is its capacity to produce intricate designs with high precision. Modern vacuum forming machines come equipped with advanced control systems that allow for better temperature regulation and uniform heating across the plastic sheet. This ensures that the material forms accurately to the mold, reducing the risk of defects and ensuring that the final product meets quality standards.

Moreover, a new home vacuum forming machine can significantly enhance production efficiency. With the ability to automate various stages of the forming process, manufacturers can achieve faster turnaround times and increased output. This automation not only saves time but also minimizes labor costs, allowing businesses to allocate resources to other critical areas of production. The integration of user-friendly interfaces and programmable settings also allows operators to quickly adjust parameters to accommodate different product designs, thus increasing flexibility in production runs.

In addition to efficiency and precision, sustainability is becoming a key consideration in modern manufacturing. Many new home vacuum forming machines are designed to work with recyclable materials, promoting environmentally friendly practices. Manufacturers can leverage this technology to create packaging solutions that not only meet consumer demand for sustainable products but also align with regulatory requirements regarding environmental impact.

Furthermore, investing in a new home vacuum forming machine can open new market opportunities. The ability to create customized packaging solutions tailored to specific products can differentiate a company from its competitors. This flexibility allows manufacturers to respond quickly to market trends and consumer preferences, thereby enhancing their competitive edge.

In conclusion, the selection of a new home vacuum forming machine represents a strategic investment for manufacturers in the packaging industry. By focusing on efficiency, precision, versatility, and sustainability, this technology offers a pathway to improved production processes and product quality, ultimately driving business growth. As the industry continues to evolve, embracing advanced machinery will be critical for companies aiming to stay ahead in a competitive market.

One of the primary benefits of a new home vacuum forming machine is its capacity to produce intricate designs with high precision. Modern vacuum forming machines come equipped with advanced control systems that allow for better temperature regulation and uniform heating across the plastic sheet. This ensures that the material forms accurately to the mold, reducing the risk of defects and ensuring that the final product meets quality standards.

Moreover, a new home vacuum forming machine can significantly enhance production efficiency. With the ability to automate various stages of the forming process, manufacturers can achieve faster turnaround times and increased output. This automation not only saves time but also minimizes labor costs, allowing businesses to allocate resources to other critical areas of production. The integration of user-friendly interfaces and programmable settings also allows operators to quickly adjust parameters to accommodate different product designs, thus increasing flexibility in production runs.

In addition to efficiency and precision, sustainability is becoming a key consideration in modern manufacturing. Many new home vacuum forming machines are designed to work with recyclable materials, promoting environmentally friendly practices. Manufacturers can leverage this technology to create packaging solutions that not only meet consumer demand for sustainable products but also align with regulatory requirements regarding environmental impact.

Furthermore, investing in a new home vacuum forming machine can open new market opportunities. The ability to create customized packaging solutions tailored to specific products can differentiate a company from its competitors. This flexibility allows manufacturers to respond quickly to market trends and consumer preferences, thereby enhancing their competitive edge.

In conclusion, the selection of a new home vacuum forming machine represents a strategic investment for manufacturers in the packaging industry. By focusing on efficiency, precision, versatility, and sustainability, this technology offers a pathway to improved production processes and product quality, ultimately driving business growth. As the industry continues to evolve, embracing advanced machinery will be critical for companies aiming to stay ahead in a competitive market.

Keywords:

Related information

The Future of Manufacturing: Investing in a New Home Vacuum Forming Machine

In the landscape of manufacturing and packaging machinery, the introduction of a new home vacuum forming machine can significantly transform production capabilities. Vacuum forming is a widely used method for creating plastic parts and packaging, which involves heating a thermoplastic sheet until it is pliable, then forming it over a mold using vacuum pressure. This technology is not only versatil

2025-07-18

Harnessing Data Analytics to Enhance Performance in Renowned Forming Equipment

Harnessing Data Analytics to Enhance Performance in Renowned Forming Equipment

Table of Contents

Introduction to Data Analytics in Forming Equipment

The Importance of Data Analytics in Manufacturing

Key Data Analytics Techniques for Forming Equipment

Real-World Case Studies of Data Analytics in Action

Challenges in Harnessing Data Analytics

Future Trends in Data Analytics

2025-07-17

Exploring the Advantages of Classy Automatic Thermoforming Machines

In the realm of packaging machinery, the classy automatic thermoforming machine stands out as a sophisticated and efficient solution for producing a wide variety of plastic products. These machines are designed to create packaging by heating plastic sheets until they become pliable and then forming them into specific shapes using molds. This process not only enhances the aesthetic appeal of the pa

2025-07-16