Popular products

Single Head Thick Sheet Vaccum Forming Machine

Category:

- Detail

- Video

-

- Commodity name: Single Head Thick Sheet Vaccum Forming Machine

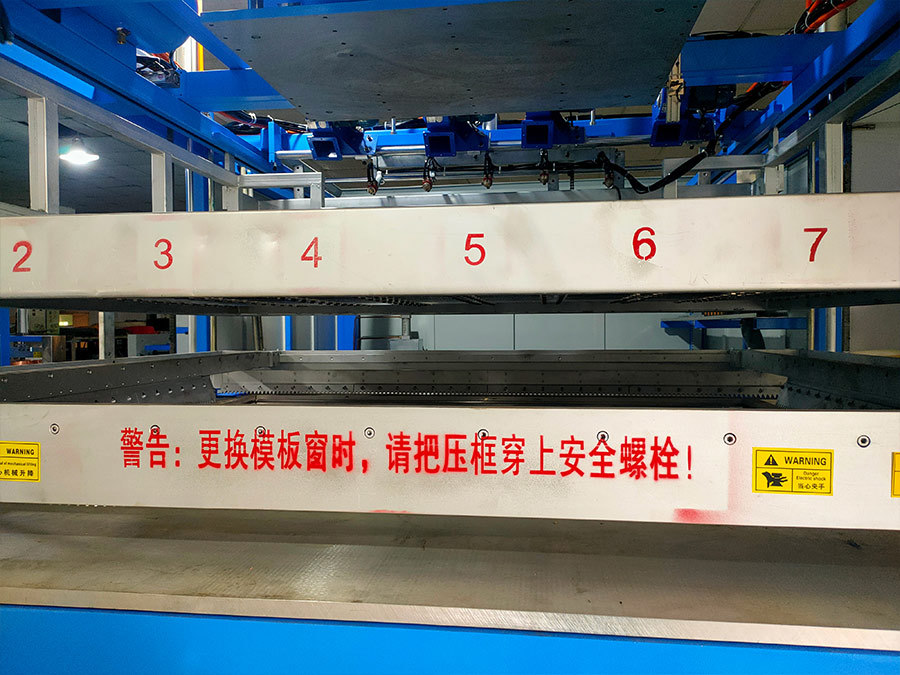

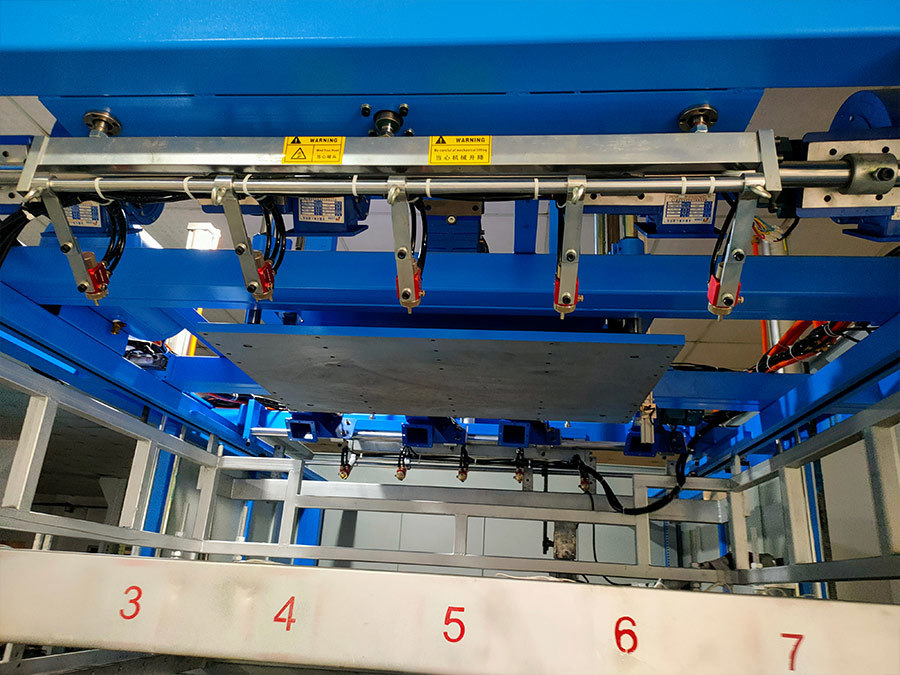

Further Observation

Equipment Features

- The double-sided heating method is used, which is mainly heated by a carbon fiber medium-wave tube. Its characteristics: synchronous light and heat, fast preheating, strong permeability, good reflection effect, power failure when not heated, and a lot of energy consumption is saved.

- The formula storage function can freely store production parameters and has the function of backing up files.

- Each independent temperature control unit controls two heating tubes, which have a voltage regulating function and are not affected by voltage fluctuations.

Application

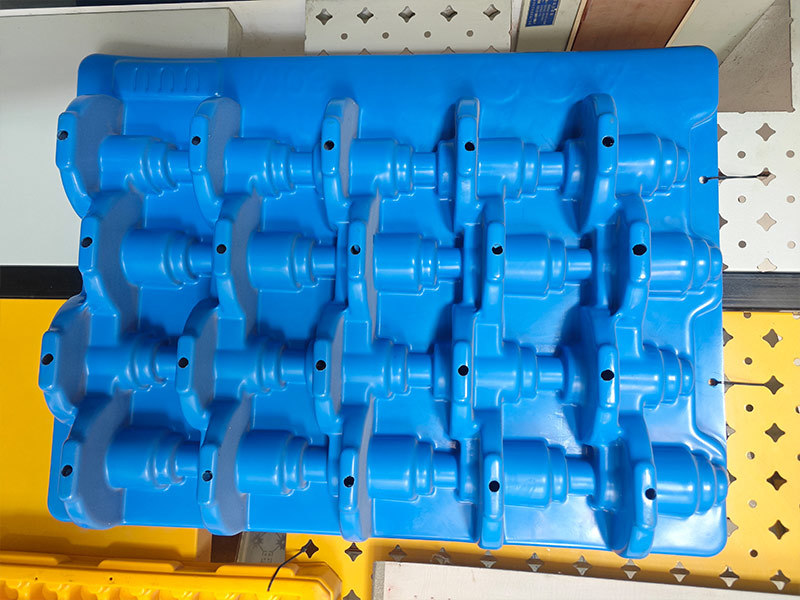

- The thick sheet vacuum blister forming machine is specially designed for HDPE, HIPS, PE, PC, ABS, PVC, PS, PET and other thermoplastic materials.

- It is widely used in the blister molding of plastic products such as automotive interior parts, turnover pallets, pallet pallets, equipment housings, aviation high-speed rail interiors, etc.

Technical Parameters

Serial number Technical parameters 1 Molding Length 2700mm ( Customizable ) 2 Molding Width 2200mm ( Customizable ) 3 Forming Height 800mm ( Customizable ) 4 Adaptive Material Thickness 1-10mm 5 Molding Method Die/punch molding 6 Furnace Power Upper furnace 140KW lower furnace 140KW (approximately) 7 Power capacity Three-phase five-wire system, 380V, 50HZ, voltage fluctuation range ±10% 8 Required Air Source Displacement 2.5m3/min 9 Machine Weight 8T

Real shot sample

Qualification

CHINA GREAT WALL (TIANJIN)QUALITY ASSURANCE CENTRE CO.,LTD.QUALITY MANAGEMENT SYSTEM CERTIFICATE

CHINA GREAT WALL (TIANJIN)QUALITY ASSURANCE CENTRE CO.,LTD.QUALITY MANAGEMENT SYSTEM CERTIFICATE

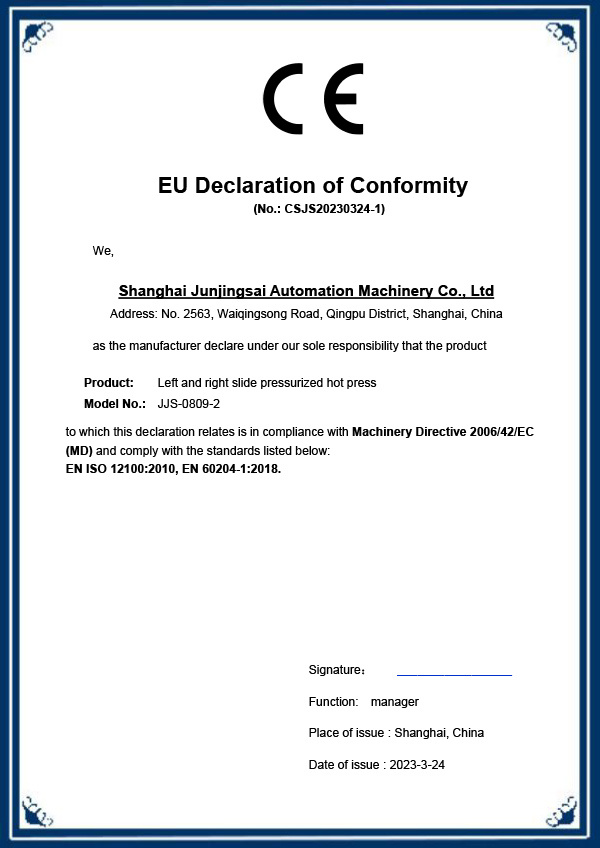

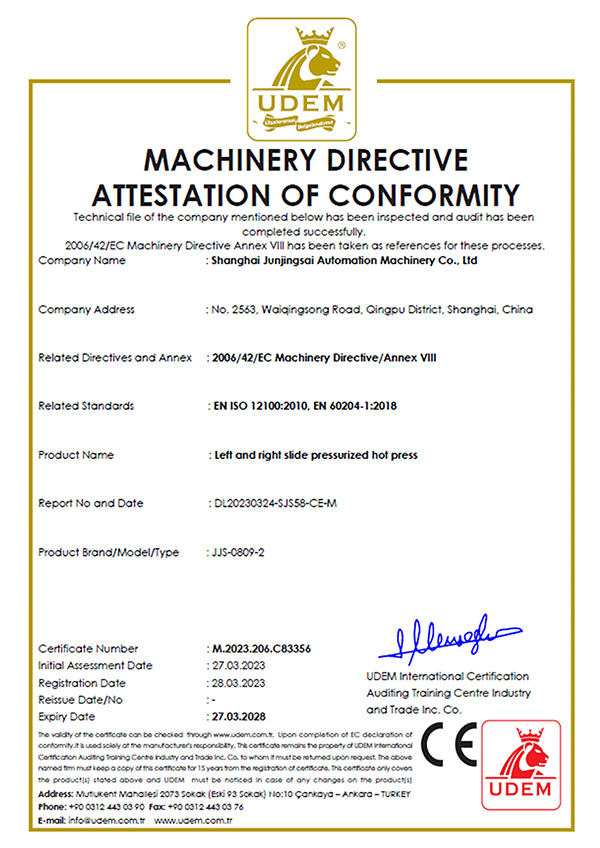

EU DECLARATION

CE certification

Product inquiry