Popular products

Fully automatic double-layer automobile air duct blister machine

Category:

- Detail

- Video

-

- Commodity name: Fully automatic double-layer automobile air duct blister machine

Over the years, it has continued to solve production process problems for customers and successfully undertaken many top 500 enterprise projects.

Further Observation

Equipment Features

- The upper and lower molds are driven by servo motors, and the linear guide rail is fully automatic for loading and unloading, which is accurately positioned and saves labor.

- Variable frequency motor moves the heating furnace to accurately adjust the moving speed of the heating furnace.

- Halogen tube heating, fast heating speed, strong permeability, according to product needs, single group temperature adjustment or regional temperature adjustment, energy saving and power saving.

- The equipment comes with a bubble blowing function to flatten the material during heating to achieve uniform wall thickness of the blister material.

Technological Process

The forklift delivers the entire stack of materials to the discharge area→ The manipulator suction cup automatically draws the sheet→ the linear guide rail accurately delivers the material to the forming station→ The heating furnace automatically moves the heating → blowing the foam to level the material forming→ Automatically delivers the finished product and automatically puts down a piece of raw material while cutting the material, and works in a circular manner.

Application

- This equipment is suitable for the processing and forming of thermoplastic materials such as ABS, HDPE, PE, PC, PS, PVC, PMMA, EVA, PP, etc.

- Widely used in automotive interior and exterior decoration parts, logistics turnover pallets, aviation interior parts, high-speed rail interior parts, equipment and instrument housings, luggage, refrigerator liner and other fields.

Technical Parameters

Serial number Technical Parameters 1 Maximum Molding Length 1300mm 2 Maximum Molding width 1000mm 3 Maximum Forming Height Up 200mm down 200mm 4 Adaptive Material Thickness 1-5mm 5 Production Speed 80-120 mold/h 6 Heatng Element Ceramic infrared heating brick 7 Power Capacity Three-phase five-wire system,380V,50HZ,Voltage fluctuation range ±10% 8 Total Power 260KW 9 Machine Dimension(L*W*H) 11560*3300*3650mm

Real shot sample

Qualification

CHINA GREAT WALL (TIANJIN)QUALITY ASSURANCE CENTRE CO.,LTD.QUALITY MANAGEMENT SYSTEM CERTIFICATE

CHINA GREAT WALL (TIANJIN)QUALITY ASSURANCE CENTRE CO.,LTD.QUALITY MANAGEMENT SYSTEM CERTIFICATE

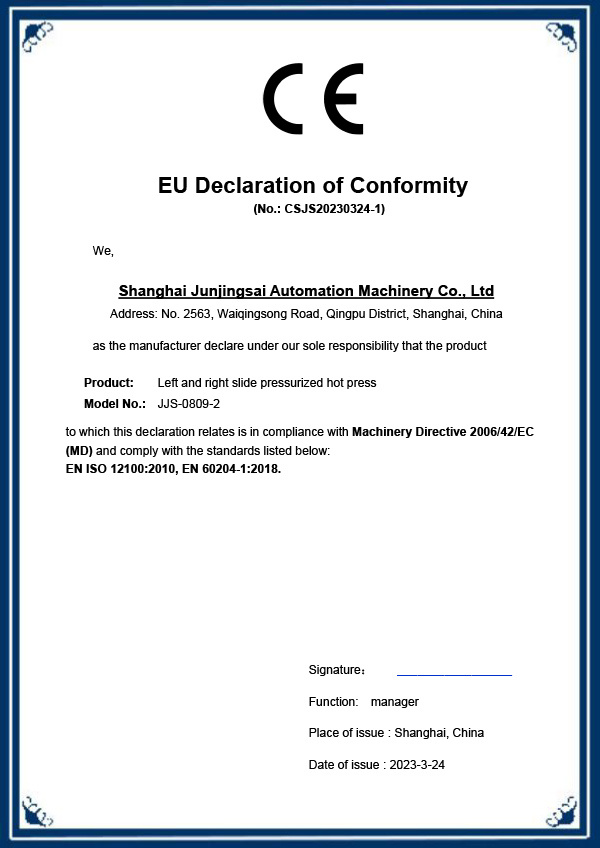

EU DECLARATION

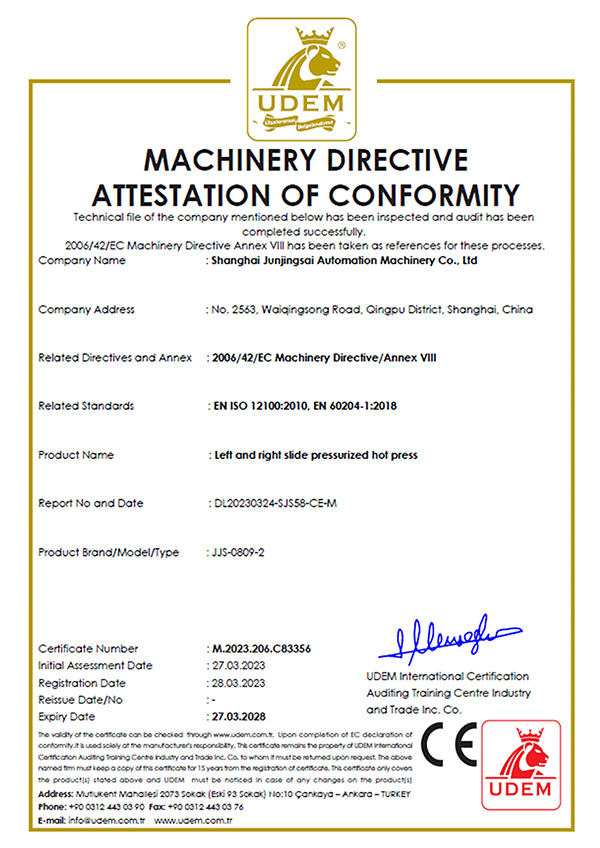

CE certification

Previous:

Product inquiry