Popular products

Fully automatic male mold laminating machine

Keywords:

Category:

- Detail

- Video

-

- Commodity name: Fully automatic male mold laminating machine

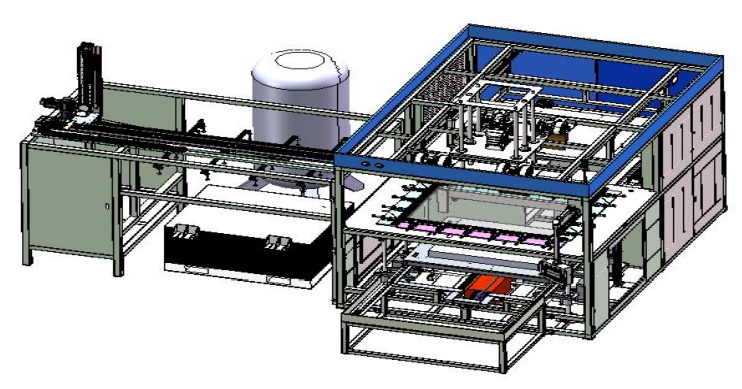

Equipment size: Probably L6080mm*W5100mm*H3740mm The plastic thermoforming machine is a highly efficient, stable, and widely applicable plastic molding equipment. It primarily uses heat to soften thermoplastic sheets, then forms them into the desired three-dimensional products through vacuum, pressure, or mechanical means.

The plastic thermoforming machine is a highly efficient, stable, and widely applicable plastic molding equipment. It primarily uses heat to soften thermoplastic sheets, then forms them into the desired three-dimensional products through vacuum, pressure, or mechanical means. This equipment is widely used in industries such as packaging, food containers, medical supplies, electronic trays, automotive interiors, and daily necessities. It meets the dual demands of large-scale production and high-precision molding, making it an indispensable piece of equipment in modern plastic processing.

In actual production, the plastic thermoforming machine offers advantages such as uniform heating, fast molding speed, and a high degree of automation. The precise temperature control system ensures consistent heating of the sheet material, effectively reducing material waste and molding defects, and improving the finished product yield. The equipment operates stably, enabling continuous production, significantly increasing overall capacity while reducing labor costs. The machine is compatible with various thermoplastic materials, such as PS, PET, PVC, and PP, offering strong flexibility and a wide range of applications to meet different product needs.

From an operation and maintenance perspective, the design emphasizes user-friendliness and safety. The intuitive control interface makes operation simpler, allowing even novice users to quickly get started. Key components are manufactured with wear-resistant and high-temperature resistant materials, extending the equipment's lifespan and reducing downtime for maintenance. The modular structure design facilitates future upgrades and functional expansion, helping businesses maintain a competitive edge in the ever-changing market.

In today's manufacturing environment, which emphasizes efficiency and sustainability, the Plastic Thermoforming Machine provides businesses with a reliable solution through its high production capacity, stable quality output, and excellent energy consumption control. Whether it's improving production efficiency or optimizing product quality and cost control, the Plastic Thermoforming Machine delivers long-term value to plastic product manufacturing and is an ideal choice for companies pursuing large-scale and refined production.

Further Observation

Equipment outline drawing

Equipment axis measurement diagram

Top view of equipment

Main parameters of equipment

Equipment size Probably L6080mm*W5100mm*H3740mm Power supply 3P+N+PE AC380+10% 50HZ Air pressure 0.5~0.6Mpa Equipment CT ≤60S Hot furnace power 132KW Number of operators 1 person Vacuum pump 200 cubic meters/hour

Real shot sample

Qualification

CHINA GREAT WALL (TIANJIN)QUALITY ASSURANCE CENTRE CO.,LTD.QUALITY MANAGEMENT SYSTEM CERTIFICATE

CHINA GREAT WALL (TIANJIN)QUALITY ASSURANCE CENTRE CO.,LTD.QUALITY MANAGEMENT SYSTEM CERTIFICATE

EU DECLARATION

CE certification

Product inquiry